In 2023, the Environmental Protection Agency (EPA) proposed new regulations for greenhouse gas emissions from Class 8 vehicles. The new regulations would require Class 8 vehicles to emit 20% fewer greenhouse gases by 2027. In the light of new regulations, pressure is mounting to reduce fleet emissions.

Environmental, Social, and Governance (ESG) reporting requirements have placed a renewed focus on emission management strategies for fleet owners looking for ways to lessen their vehicles’ impact on the environment. While transitioning to electric vehicles (EV) may be a desirable long-term goal, it’s not always practical or realistic for fleets operating in the current market.

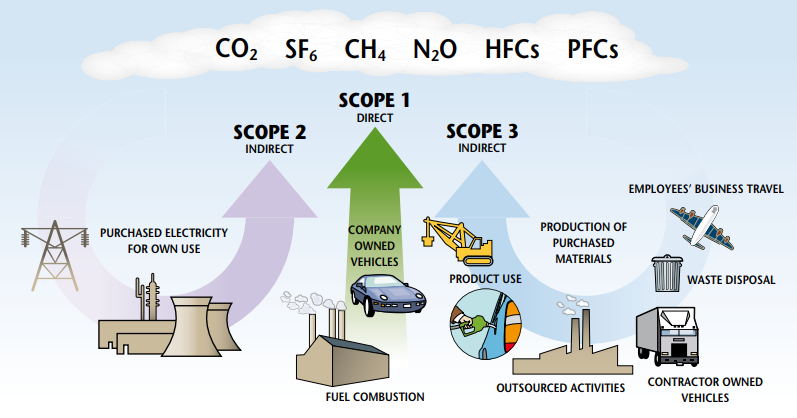

However, fleet owners can take steps to reduce emissions on Class 8 vehicles, improve Scope 3 carbon emissions for its customers, and build a competitive advantage.

Fleet Emissions and the STEER Act

New legislation has emerged to help equip fleets with technology that will help reduce emissions.

The Supporting Trucking Efficiency and Emission Reductions (STEER) Act, introduced in the U.S. House in July 2021, is designed to reduce emissions by incentivizing truck companies to buy and install fuel-efficient technologies on Class 8 trucks.

Under the STEER Act, the U.S. Department of Energy (DOE) would provide $500 million over five years for vouchers to cover the expense. A draft of the legislation states that the voucher amounts for each technology included in the bill will cover the lesser of:

- $4,000 or 75% of costs per unit for fleets operating 10 trucks or fewer.

- $3,500 or 72.5% of costs per unit for fleets operating 50 trucks or fewer.

- $3,000 or 70% of costs per unit for fleets operating 100 trucks or fewer.

- $2,500 or 67.5% of costs per unit for fleets operating more than 100 trucks.

5 Ways to Reduce Fleet Emissions

Going electric is one way to reduce emissions.

But the truth is that transitioning to EVs is not realistic for most fleets in the near term.

Adding EVs to a fleet requires a substantial investment. Electric Class 8s cost $400,000 to $600,000, compared to about $150,000 for conventional diesel trucks.

About $220,000 of that expense is for the electric powertrain alone. Another added expense is the need for electric vehicle infrastructure, such as charging stations, which cost about $20,000 each.

There are also concerns that if drivers have to stop every 150 to 250 miles to charge their trucks, driver shortages will increase. This is why it’s important to consider using technologies that improve fuel efficiency and lower emissions in existing vehicles.

Fortunately, there are five other ways to reduce emissions that are more practical and realistic for most fleets in the short term.

1. Improve Truck Aerodynamics

Improving aerodynamics is one of the most effective ways to reduce fuel consumption and emissions both today and into the future with EVs.

Aerodynamic drag accounts for over half of a truck’s fuel consumption at highway speeds. The good news is that using multiple aerodynamic devices to reduce drag can save the trucking industry about $10 billion in diesel fuel expenses.

These devices include:

- Roof fairings to minimize the turbulence created by the cab.

- Wheel covers that allow air to flow past the tires.

- Active aerodynamics devices that automatically adjust to the changing aerodynamic needs.

One example of an active aerodynamic device for Class 8 tractors is TruckWings, a device that automatically closes the gap between the cab and trailer. TruckWings automatically deploy when speed exceeds 52 mph and retracts when speed is below 50 mph.

This means drivers don’t need to take their eyes off the road or their hands off the wheel.

Here are some of TruckWings’ proven benefits:

- Improves driver experience: Fully-automated TruckWings improve stability, especially in crosswinds, and don’t require driver interaction.

- Helps fleet owners meet ESG goals: Each TruckWing reduces 20,000 lbs/yr in carbon emissions.

- Offers durability with minimal maintenance: Aerospace-grade aluminum has proven durability of almost half a billion miles driven and outperforms side extenders.

- Provides real-time data: A cloud-connected telematics device features customer dashboards for 100% transparency.

- Reduces fuel costs: TruckWings has shown proven savings of 3-6% mpg, resulting in millions of dollars saved per fleet.

2. Invest in Telematics

The technology of communicating, collecting, and storing information via telecommunication devices is known as telematics.

In trucking, telematics monitors engine diagnostics and the hours a vehicle runs. This helps fleet managers keep track of all vehicle updates and required maintenance.

3. Optimize Trucking Routes

An efficient routing plan can help reduce fuel consumption, emissions, and costs.

GPS technology has advanced, allowing for quicker travel and fewer stops, resulting in a 30% reduction in carbon emissions during each trip.

4. Monitor and Improve Driver Habits

The most common cause of fuel waste is driver behavior.

Teaching and encouraging proper driving habits can result in a significant reduction in fuel consumption. Aggressive drivers who accelerate and brake rapidly use up to 30% more fuel.

Additionally, a tractor-trailer uses 20% less energy to move at 55 mph than 62 mph. And an idling diesel vehicle uses half a gallon of fuel an hour.

Cutting idling can save up to 5% of fuel costs, amounting to thousands of dollars in savings per year.

5. Upgrade to Newer Vehicles

Older vehicles are less fuel-efficient than newer models, so upgrading your fleet can reduce emissions and fuel consumption.

A recent report from Fleet Advantage shows upgrading to a 2021 model from a 2016 model would reduce CO2 by 21 metric tons, resulting in $16,856 in savings per truck.

Reduce Your Fleet Emissions

There’s no one-size-fits-all solution to reducing fleet emissions, but these five steps are a good place to start.

You can make a significant impact on your fleet’s carbon footprint by making even small modifications. And as electric vehicles become more prevalent, now is the time to start planning for the future.