Mitigating waste, conserving resources, and reducing pollution are not new challenges for the trucking industry. Commercial trucks comprised nearly 30% of transport emissions in 2018, making the sector one of the fastest-growing sources of greenhouse gases in the United States. Given the increase in public awareness about the impact of climate change, sustainable trucking is now a trending topic.

The trucking industry is under increasing pressure to reduce its emissions. This pressure comes from the government and the public, but it also comes from truckers.

In a study by digital freight network Convoy, 61% of surveyed drivers said that climate change is of some or a great deal of importance.

In this post, we’ll look at four sustainable trucking trends and technologies that could help minimize emissions.

4 Trends Driving Sustainable Trucking

With more than 300 companies signing the Climate Pledge to achieve carbon net-zero status by 2040, sustainable trucking is top of mind for many businesses.

As part of its study, Convoy surveyed dispatchers, drivers, and owner-operators from 700 SMB trucking companies. Convoy’s goal was to understand the current state of sustainability in trucking.

The findings revealed four key trends affecting sustainable trucking:

1. New (And Not So New) Government Regulations

Government regulations are the most significant driver of sustainable trucking practices.

Just over 25% of respondents in the March 2022 Convoy survey listed regulations as their top reason for reducing carbon emissions, up from 19.2% in August 2021. New environmental regulations focused on curbing emissions are currently under consideration at the national level. And state-level regulations, like the California Air Resources Board (CARB)’s zero emissions goal, are a factor driving sustainable trucking practices.

Here are a few to keep in mind:

- In April 2022, the federal government announced new vehicle fuel economy standards for model years 2024-2026. The measures will require an industry average of 49 mpg for new passenger cars and light trucks by 2026. The rule aims to increase fuel efficiency by 8% annually in 2024 and 2025 and 10% in 2026.

- The California Air Resources Board (CARB) is working towards zero emissions for medium and heavy-duty fleets by 2035. The new regulation will significantly impact the transportation industry as early as 2024, with California planning to restrict fleets from deploying non-zero emission vehicles in drayage operations starting Jan.1 of that year.

- SmartWay, an EPA program introduced in 2004, focuses on reducing emissions across the supply chain by enabling transport companies to track, document, and share fuel use and freight emissions. SmartWay partners enjoy many benefits, including help demonstrating their commitment to improving freight sustainability, and reducing CO2, NOx, and PM emissions.

2. Rising Diesel Costs

Diesel costs are high and not likely to decrease any time soon.

Three-quarters of all commercial trucks use diesel, moving nearly 70% of America’s freight tonnage. Since this likely won’t change in the next 10-20 years, trucking companies need to find ways to cut fuel consumption to reduce costs and emissions.

Nearly all of the nation’s largest tractor-trailers — class 8 trucks — are powered by diesel, and about 75% of small-to-medium-duty commercial trucks use diesel. Depending on your state, a gallon of diesel averages $5 to $6, meaning the average cost to fill the tank can range from $700 to $1,400, depending on the truck’s size.

This makes achieving maximum fuel efficiency a top priority for truckers and trucking companies.

3. More Pressure to Take Action

Awareness of climate change and public pressure are still big factors driving sustainable initiatives for many in the trucking industry.

In Convoy’s survey, 38% of respondents reported feeling pressure to reduce carbon emissions, up from 35% in 2021. Respondents cited government regulation as the top reason for feeling pressure to reduce carbon emissions, second to awareness about the environmental impact of emissions.

4. Efforts to Reduce Empty Miles

Convoy’s research found that 35% of truck miles are empty miles, with drivers driving, on average, between 100 and 400 miles empty.

Reducing empty miles by just 1% saves over 100 gallons of fuel. It’s why nearly 93% of respondents in the Convoy survey said reducing empty miles is moderately important, important, or very important to their business.

Empty miles have a huge environmental impact, contributing to 87 million metric tons of carbon emissions annually. But they also represent an opportunity when it comes to reducing emissions and improving sustainability in trucking.

Sustainable Trucking Technologies

Promising new technologies like active aerodynamics, alternative fuel vehicles, and telematics can help trucking companies reduce emissions, comply with government regulations, and save money.

We unpack all three below.

1. Active Aerodynamics

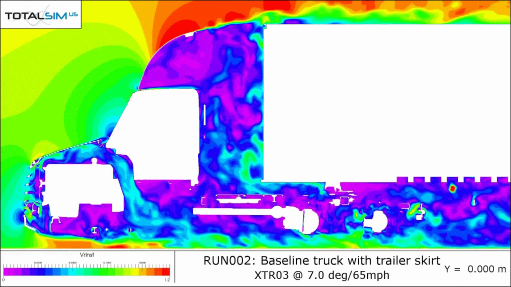

Active aerodynamics is a term commonly associated with improving the fuel economy of cars by reducing drag, and it can also apply to trucks.

Due to the considerable size and weight of trucks, semi-truck aerodynamics are more challenging to achieve. Recent research by the U.S. Department of Energy (DOE) revealed that a truck engine uses 85% of the energy it produces to overcome aerodynamic drag and rolling resistance.

To fix this, TruckWings, a tractor-mounted aerodynamic device created by TruckLabs, decreases downstream turbulence and drag. The device eliminates higher crosswind angles in the tractor-trailer gap by controlling airflow around the cab.

TruckWings works without driver interaction by extending winglets from the side of the truck based on vehicle speed and smart sensors, automatically unfolding once highway speeds reach 52 mph and retracting when speed goes below 50 mph. This can result in fuel savings of up to 4.1% — the equivalent of 20,000 pounds of CO2 per year.

2. Alternative Fuel Vehicles (AFVs)

With diesel costs and regulations around emissions, many trucking companies are turning to alternative fuel vehicles (AFVs). AFVs include electric, hydrogen-electric, and renewable natural gas vehicles.

They emit just under 4,100 pounds of CO2 equivalent annually versus the 11,435 pounds of CO2 emitted by gas vehicles. AFVs are cost-prohibitive for many SMB trucking companies, with an up-front cost per vehicle of $200,000 to $800,000, versus $40,000 to $120,000 for the base model of a new diesel-powered semi-truck.

For this reason, equipping your existing fleet with tools to help reduce drag and improve fuel economy is a more cost-effective way to reduce emissions in the short term.

3. Telematics in Trucking

Telematics is essential for many trucking companies looking to reduce emissions and improve sustainability.

The software uses sensors, GPS technology, and other data-tracking technologies to help companies:

- Track their vehicles in real time

- Optimize routes to reduce empty miles

- Identify patterns and areas for improvement

Data collected includes:

- Fuel consumption

- Real-time truck location

- Idling time

Sustainability Challenges in Trucking

Sustainability challenges are becoming synonymous with business challenges for truckers.

Pressure is mounting for trucking companies to prove their commitment to reducing carbon emissions and identify problematic practices within the supply chain.

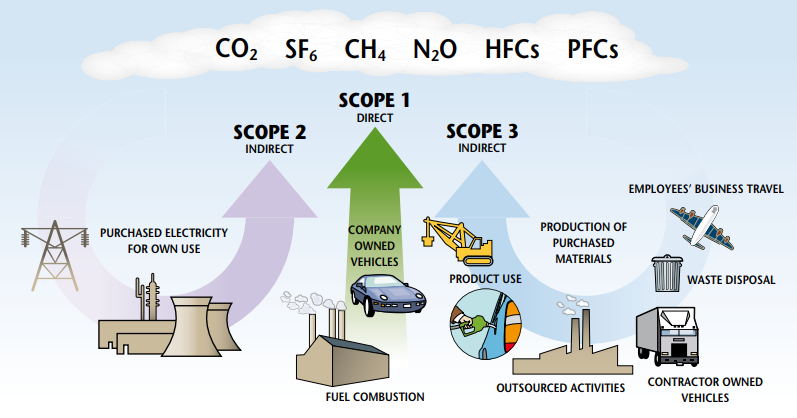

Understanding how scope 1, 2, and 3 emissions impact the environment can help you make better choices for your business and the environment.

Here’s a brief breakdown of each type:

- Scope 1: Direct emissions from company-owned or controlled sources

- Scope 2: Indirect emissions from using electricity, heat, or steam

- Scope 3: Other indirect emissions from the entire value chain

The best way to address Scope 3 emissions is to partner with sustainable trucking companies committed to reducing their emissions.

The STEER Act Can Help

US Rep. Rodney Davis introduced the Supporting Trucking Efficiency and Emission Reductions (STEER) Act in 2021.

It’s a $500 million voucher program focused on helping truckers and trucking companies retrofit their existing class 8 trucks with fuel-efficient technologies.

The STEER Act aims to help fleet owners reduce emissions and move towards more sustainable practices by incentivizing emission-reducing technologies. So even if you aren’t ready to move to AFVs, you may qualify for a voucher to cover the technology needed to retrofit your existing fleet.

Examples of Sustainable Trucking Companies

Here are three examples of trucking companies prioritizing sustainability, starting with Ryder System, Inc., a company that conducted a recent test of our TruckWings technology.

Ryder System, Inc.

Ryder partnered with TruckLabs to conduct a 60-truck on-road test of TruckWings.

The controlled pilot fuel test assessed whether TruckWings could improve Ryder’s fuel economy and reduce the environmental impact of its fleet of over 200,000 trucks. Ryder compared the relative performance of a truck before and after installing the technology.

After evaluating the results, Ryder realized an improvement of over 4% in net mpg.

Werner Enterprises

Werner Enterprises is a US-based transportation and logistics company that uses technology to reduce CO2 emissions across its fleet of 8,000 trucks and 24,000 trailers.

Werner uses automated manual transmissions to boost fuel economy by 1-3%, predictive maintenance to monitor performance and keep trucks at maximum efficiency, and GPS trailer tracking to increase hauling efficiency. They’ve also begun piloting solar panels on their trucks to help extend battery life and reduce jump-starts.

DHL Express

DHL Express, headquartered in Germany, wants to reduce greenhouse gas emissions to below 29 million tons by 2030.

They aim to reach net-zero emissions by 2050. In addition to addressing Scope 3 emissions by auditing service providers along the supply chain, the company has begun retrofitting its fleet of medium- and heavy-duty trucks with solar panel mats that regulate the transfer of energy from the alternator to the battery.

The mats, expected to reduce greenhouse gas emissions for each vehicle by 2,000 pounds annually, also have sensors that collect data on fuel and emissions.

A Pathway to Sustainability

Sustainable trucking leaders show that there are many ways to reduce your emissions.

From active aerodynamics to solar panels to ATVs, the options to reduce your carbon footprint are numerous. As government, consumer, and industry awareness about the industry’s impact on climate change grows, so will the pressure on trucking companies to mitigate their emissions.

Products like TruckWings can help your company take the first steps towards reducing emissions and fuel costs. The companies that don’t begin to invest in more environmentally-friendly technologies will fall behind as the industry moves towards a more sustainable future.